Medical Components FAQ

Medical Components FAQ

With continuous advancements in medical technology, the correct understanding of medical consumable components and their specific functions has become increasingly important. For healthcare professionals, R&D engineers, and procurement personnel, enhancing knowledge about these components ensures accurate operation, maintains product quality, and ensures patient safety.

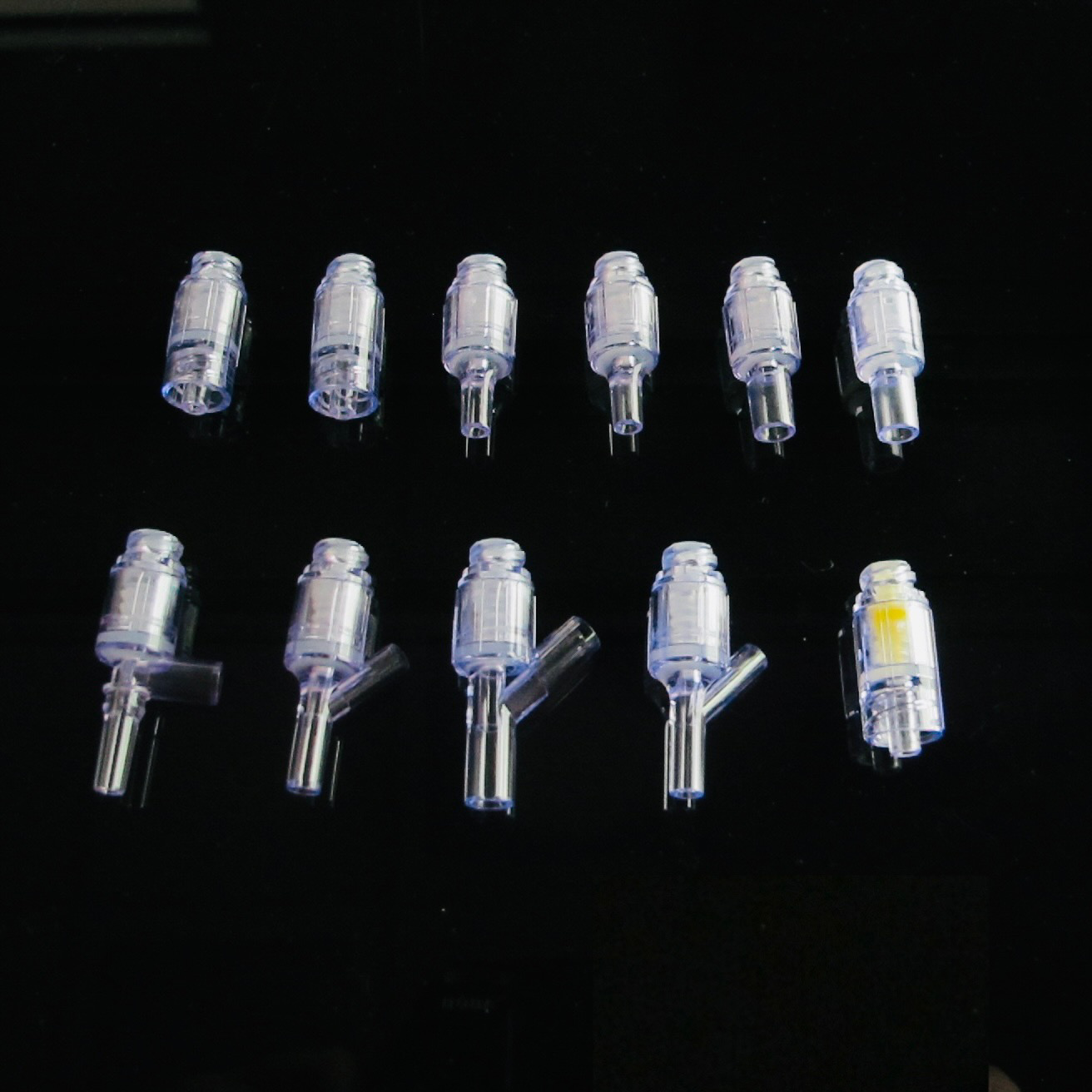

However, confusion often arises among healthcare professionals, R&D engineers, and procurement teams regarding the correct identification and application of certain components, particularly those with similar appearances but different functions. For instance, Needle-free Connectors and Check Valves are frequently mistaken for one another, potentially leading to operational errors or safety risks.

To address this issue, CHI FENG has developed this comprehensive FAQ library, clearly outlining the usage, characteristics, functionalities, appropriate scenarios, and differences among various medical consumable components. Our goal is to effectively enhance your team's professional knowledge and operational efficiency, helping you quickly grasp critical information.

Benefits of Using This FAQ:

1. Rapid Clarification of Confusion

Clearly explains common misunderstandings about components frequently confused (e.g., Needle-free Connectors vs. Check Valves), significantly reducing the risk of errors.

2. Enhanced Communication Efficiency

Provides standardized and professional responses to common inquiries, empowering sales and customer service teams to swiftly and accurately address customer questions, enhancing overall service quality.

3. Accelerated Product Development

Assists R&D personnel in quickly building deeper expertise in medical consumable components, facilitating faster and safer product development.

3. Reduced Training Time

Enables new staff or those without medical backgrounds, including procurement and R&D personnel, to quickly grasp core concepts, thereby shortening onboarding and training times.

Through this FAQ library, CHI FENG aims to enhance your team's professional knowledge, support operational efficiency, and ensure product safety and quality. Should you have any further questions or requirements, please feel free to contact us!

- The design of needle-free connectors often includes features that reduce liquid residue, making them applicable in various areas, including:

- Intravenous (IV) therapy: Needle-free connectors can reduce the amount of liquid residue within the connector during the IV therapy, minimizing medication wastage and the risk of cross-contamination.

- Blood collection: Needle-free connectors can be used in blood collection systems, such as during blood dialysis or blood testing. Their design helps reduce blood residue within the connector, improving sample accuracy and reliability.

- Injection and infusion: Needle-free connectors are beneficial for administering injections or infusing fluids. They help minimize residual drops, ensuring accurate medication dosing and smooth, fluid administration.

- Blood product transfusion: When transfusing blood or blood products, needle-free connectors can reduce the amount of residual blood within the infusion system, enhancing blood safety and quality.

- Infusion pumps and drainage systems: Needle-free connectors can be used with infusion pumps and drainage systems, effectively reducing liquid residue and backflow within the connector and ensuring the system's smooth operation.

- The reduced liquid residue feature of needle-free connectors provides advantages in various medical applications, offering safer and more reliable fluid administration and blood management.

- Our Gen2 needle-free connector only has 0.016ml dead space/ liquid residue.

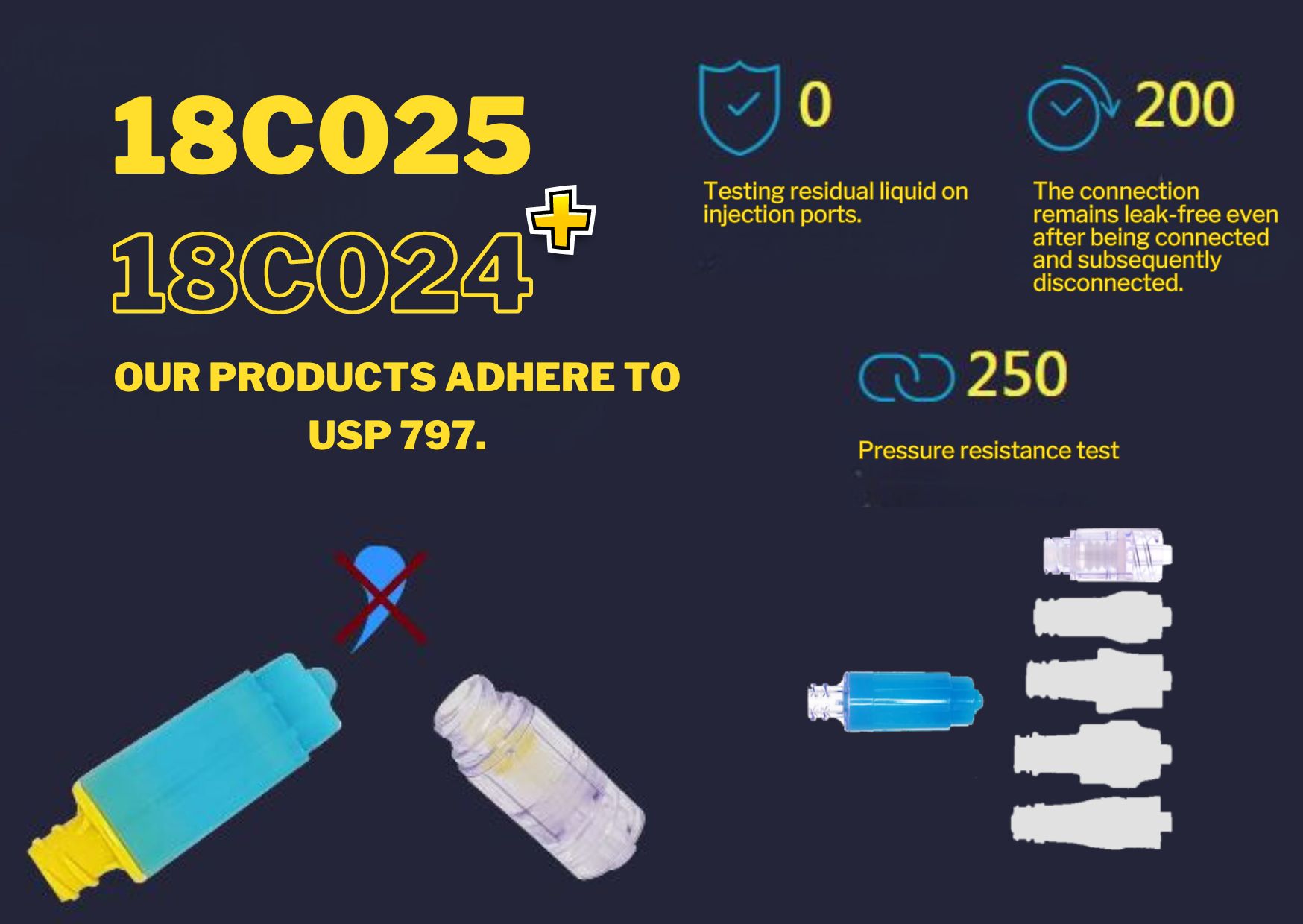

- In the application of chemotherapy infusion and drug preparation, it is generally required to use products that meet at least the USP 797 standard.

- USP 797 Overview:

- USP 797 is a set of guidelines established by the United States Pharmacopeia (USP).

- It provides detailed standards for the preparation of sterile medications.

- Focuses on safety, quality, and hygiene requirements for compounding and infusion.

- High-Risk Medical Procedures:

- Chemotherapy infusion and drug preparation are considered high-risk medical procedures.

- Patient treatment outcomes and safety are of paramount importance.

- Benefits of USP 797-Compliant Products:

- Products compliant with USP 797 offer higher quality assurance.

- Ensures sterility and aseptic handling of medications during chemotherapy.

- Reduces the risk of cross-contamination and other potential hazards.

- Global Standards and Regulations:

- Besides USP 797, other relevant standards and regulations may exist in different regions or countries.

- Compliance depends on specific healthcare facilities and treatment protocols.

- Essential for Safety and Effectiveness:

- To ensure the safety and effectiveness of chemotherapy infusion and drug preparation.

- Using products that meet applicable standards is essential.

- Note: The choice of specific standards may vary based on the healthcare facility and treatment protocols, and compliance with these standards is crucial for maintaining high-quality and safe medical procedures.

- See our CSTD Products here!

- For neutral products, you can choose the second-generation needle-free product, which protects the patient and prevents blood from flowing back into the cavity even when the hand is raised, making it less likely to accumulate blood.

- For more details, please go to the product page: Gen2 needle-free safety infusion connector.