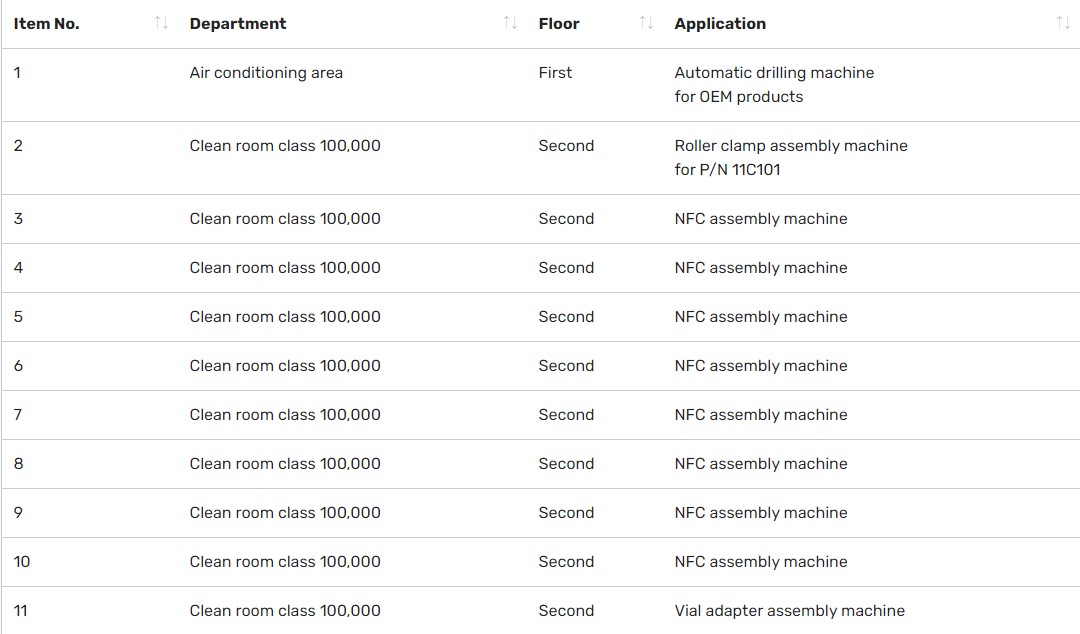

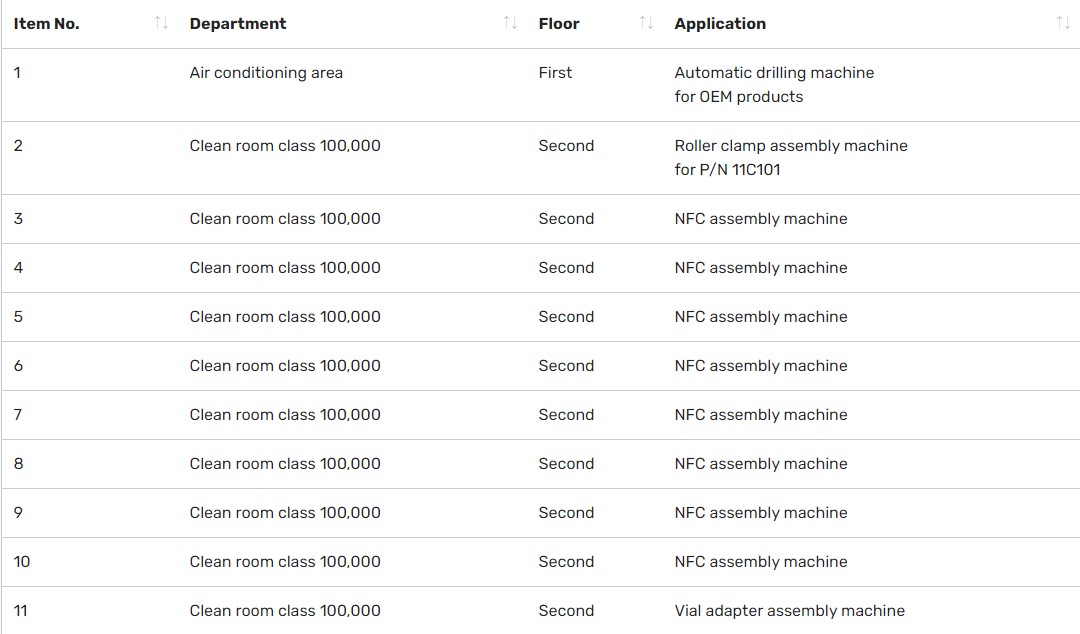

Auto Assembly Machines Equipment List

Auto Assembly Machines Equipment List

-

Definition of Class 100,000 Cleanroom Standards:

-

Air Exchange Rate

-

For a Class 100,000 cleanroom, the air exchange rate should not be less than 15 exchanges per hour, with air purification time not exceeding 40 minutes after each exchange. A higher air exchange rate results in a faster dilution and expulsion of indoor air pollutants, leading to a more effective cleanroom environment.

-

Particle Count per Unit Volume

-

In a Class 100,000 cleanroom, the particle count of particles greater than or equal to 0.5 micrometers should not exceed 3,500,000 per cubic meter, and particles greater than or equal to 5 micrometers should not exceed 20,000 per cubic meter. A lower particle count contributes to a better cleanroom environment.

-

Maximum Allowable Microbial Count

-

For a Class 100,000 cleanroom, the airborne bacteria count should not exceed 500 per cubic meter, and the settle plate count should not exceed 10 per culture dish. A lower microbial count minimizes contamination risk to products.

-

Pressure Differential

-

Pressure differentials in a Class 100,000 cleanroom: Consistent pressure differentials are maintained between cleanroom areas of the same cleanliness level. The pressure differential between adjacent cleanrooms with different cleanliness levels should be ≥5 Pa, and between a Class 100,000 cleanroom and a non-cleanroom area should be ≥10 Pa. A larger pressure differential makes it more difficult for external contaminants to enter the cleanroom.

-

The applications of a Class 100,000 cleanroom are extensive and include:

-

Production in high-tech industries such as semiconductor, electronics, and optics.

-

Manufacturing in industries such as pharmaceuticals, biopharmaceuticals, food, and cosmetics.

-

Production in fields like aerospace, navigation, and defense.

-

The construction and operation of a Class 100,000 cleanroom require specialized technical expertise and equipment to ensure it achieves the intended cleanliness standards.